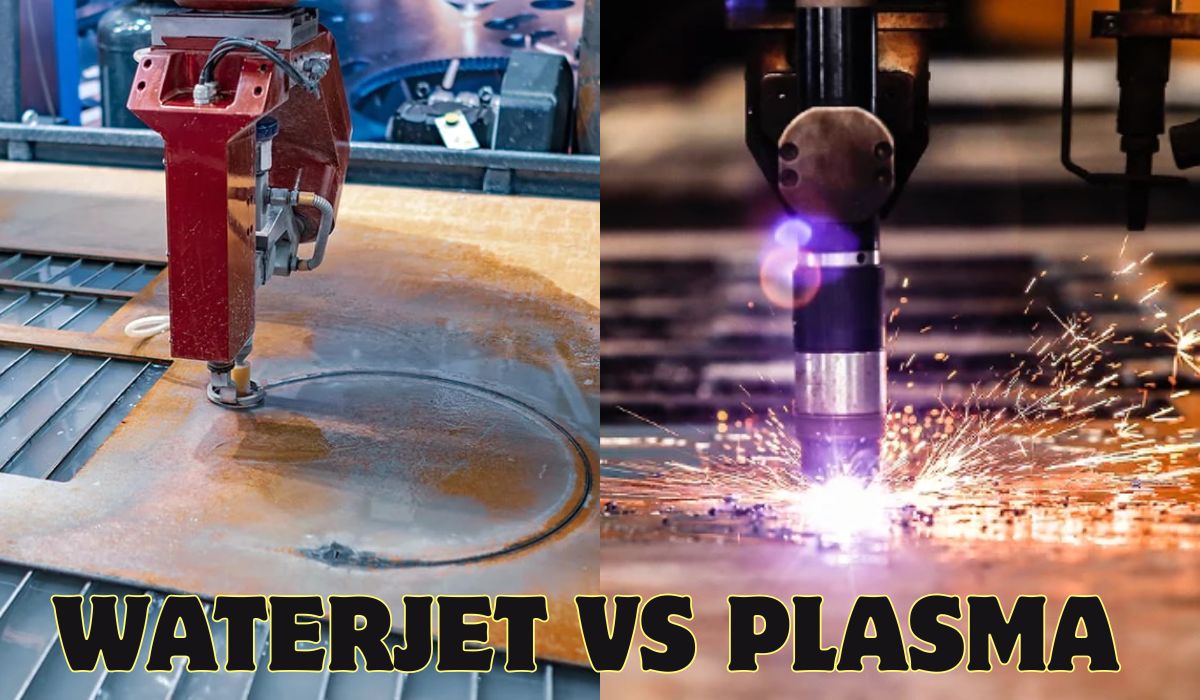

Choosing the proper cutting method can make or break your manufacturing project. Two of the most popular industrial cutting technologies—waterjet and plasma cutting—each offer distinct advantages that can significantly impact your project’s success, timeline, and budget.

Both methods have revolutionized how manufacturers approach material cutting, but they serve different purposes and excel in various scenarios. Understanding their key differences will help you select the optimal cutting solution for your specific needs.

This comprehensive comparison will examine the fundamental differences between waterjet and plasma cutting, covering everything from material compatibility and precision to speed and cost considerations. By the end, you’ll have the knowledge needed to make an informed decision for your next cutting project.

How Waterjet Cutting Works

Waterjet cutting utilizes high-pressure water streams, typically pressurized to 60,000-90,000 PSI, to slice through materials. For harder materials, the system incorporates an abrasive material—usually garnet—that acts as a cutting agent alongside the water stream.

This process operates as a “cold cutting” method, meaning it generates no heat during the cutting process. The high-pressure water and abrasives create a precise erosion process that can cut through virtually any material without altering its structural properties or creating heat-affected zones.

The precision of waterjet cutting comes from the extremely narrow kerf (cut width) and the computer-controlled cutting head, which can follow intricate patterns with exceptional accuracy.

How Plasma Cutting Works

Plasma cutting employs a high-temperature plasma arc to melt and blow away material. The process begins when compressed gas passes through a constricted opening, creating an electric arc that transforms the gas into plasma—a fourth state of matter that can reach temperatures exceeding 20,000°F.

This thermal cutting process works exclusively on electrically conductive materials, primarily metals. The plasma arc melts the material while the high-velocity gas stream blows away the molten metal, creating the cut.

The speed and efficiency of plasma cutting make it ideal for high-volume production environments where rapid material processing is essential.

Material Compatibility Comparison

Waterjet Capabilities

Waterjet cutting stands out for its remarkable versatility in material compatibility. This cutting method can process:

- All types of metals, regardless of hardness or thickness

- Natural materials, including stone, glass, ceramic, and wood

- Synthetic materials such as composites, plastics, and rubber

- Specialized materials like titanium, Inconel, and hardened steels

- Even food products in specialized applications

The cold cutting process means material properties remain unchanged, making waterjet ideal for materials sensitive to heat treatment.

Plasma Capabilities

Plasma cutting focuses specifically on conductive metals:

- Steel and stainless steel (all grades)

- Aluminum and aluminum alloys

- Brass and bronze

- Copper and copper alloys

- Other conductive metals

While plasma cutting cannot process non-conductive materials like ceramics, glass, or plastics, it excels at cutting the metals it can handle, particularly in thicker sections.

Speed and Efficiency Analysis

Plasma cutting delivers superior speed, especially when working with thicker materials. The thermal cutting process can slice through thick steel plates much faster than waterjet cutting, making it ideal for high-volume production environments.

Waterjet cutting operates at slower speeds due to the erosion-based cutting process. However, this slower speed contributes to the superior edge quality and precision that waterjet cutting provides.

For projects prioritizing rapid turnaround times and working with standard metal fabrication, plasma cutting offers significant time savings. Conversely, when precision and surface finish quality are paramount, the slower waterjet process delivers superior results.

Precision and Accuracy Differences

Waterjet cutting achieves exceptional precision, with tolerances typically within +/- 0.005 inches. The cold cutting process and narrow kerf width enable intricate cuts and complex geometries with minimal material waste.

Plasma cutting offers good accuracy, generally within +/- 0.01 to 0.030 inches. While this precision suits many applications, it may struggle with very intricate cuts or when maintaining tight tolerances on thicker materials.

The heat-affected zone created by plasma cutting can also introduce slight warping or distortion, particularly on thin materials, whereas waterjet cutting eliminates this concern.

Cost Considerations

Initial Investment

Plasma cutting systems generally require lower initial capital investment compared to waterjet systems. The simpler technology and fewer components make plasma cutters more accessible for smaller operations.

Waterjet systems involve higher upfront costs due to the complex high-pressure pumps, cutting heads, and abrasive handling systems required for operation.

Operating Costs

Plasma cutting typically offers lower operating costs per cut, especially for standard metal cutting applications. Consumables include electrodes, nozzles, and gas, which are relatively inexpensive.

Waterjet cutting involves higher operating costs due to abrasive consumption (garnet), high-pressure pump maintenance, and increased energy consumption. However, these costs may be justified by the superior cut quality and material versatility.

Application-Specific Recommendations

Choose Plasma Cutting For:

- High-volume metal fabrication projects

- Rapid prototyping of metal components

- Construction and structural steel cutting

- Automotive repair and salvage operations

- Projects where speed takes priority over precision

- Budget-conscious operations with primarily metal cutting needs

Choose Waterjet Cutting For:

- Precision cutting of intricate shapes and patterns

- Multi-material cutting requirements

- Heat-sensitive materials that cannot withstand thermal cutting

- Applications requiring superior edge quality

- Thick, hard materials that challenge other cutting methods

- Projects where dimensional accuracy is critical

FAQs About Waterjet vs Plasma

Can a waterjet cut as thick as a plasma?

Waterjet cutting can handle extremely thick materials, often exceeding plasma cutting capabilities. While plasma cutting efficiency decreases with thickness, waterjet maintains consistent cut quality regardless of material thickness.

Which method produces better edge quality?

Waterjet cutting consistently produces superior edge quality with minimal to no post-processing required. Plasma cutting may require additional finishing work, particularly on thicker materials or when precise edge requirements are necessary.

Is plasma cutting consistently faster than waterjet?

Generally, yes. Plasma cutting significantly outpaces waterjet cutting, especially on thicker materials. However, the time savings must be weighed against potential post-processing requirements for edge finishing.

Which cutting method is more cost-effective?

Cost-effectiveness depends on your specific requirements. Plasma cutting offers lower initial investment and operating costs for metal cutting applications. Waterjet cutting provides better value when material versatility, precision, and edge quality are priorities.

Can either method cut reflective materials?

Waterjet cutting handles reflective materials like polished metals without issue. Plasma cutting can cut reflective metals, but may require specific techniques or equipment adjustments to manage reflection-related challenges.

Making the Right Choice for Your Project

The decision between waterjet and plasma cutting ultimately depends on your specific project requirements, budget constraints, and long-term operational needs.

Evaluate your primary materials, required precision levels, production volume, and budget to determine which cutting method aligns best with your objectives. Consider consulting with cutting service providers who can assess your specific needs and recommend the optimal solution.

Both technologies continue evolving, with improvements in speed, precision, and cost-effectiveness. Staying informed about these advancements will help you make the best cutting technology decisions for your future projects.